View A Sampling Of Yushin Products That We Carry

Why is a several hundred kilogram robot needed to pick a molded part of just a few grams?

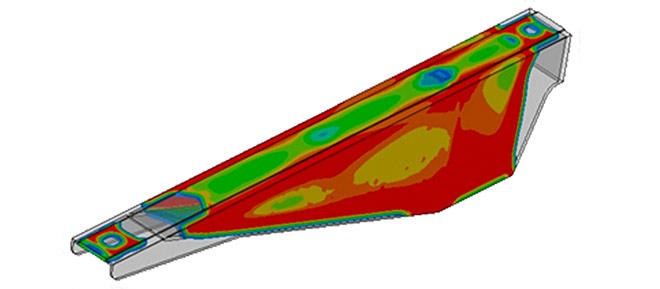

To answer this question, Yushin sought an application-specific robot through its Optimum Design approach. Design Optimization is what Yushin calls its use of CAE (Computer—Aided Engineering) to determine the theoretically best configuration of a robot based on its mechanisms and movements, rather than relying solely on designer experience. This approach has been used in recent years to make aircraft and automobiles lighter and more reliable. Curiously enough, we have often been amazed by how closely optimized designs resemble trees and animals in the natural world. Designed to deliver speeds and safety unachievable with predecessor models, we are confident that the HSA series will usher in a new era in take-out robots.

Why is a several hundred kilogram robot needed to pick a molded part of just a few grams?

To answer this question, Yushin sought an application-specific robot through its Optimum Design approach. Design Optimization is what Yushin calls its use of CAE (Computer—Aided Engineering) to determine the theoretically best configuration of a robot based on its mechanisms and movements, rather than relying solely on designer experience. This approach has been used in recent years to make aircraft and automobiles lighter and more reliable. Curiously enough, we have often been amazed by how closely optimized designs resemble trees and animals in the natural world. Designed to deliver speeds and safety unachievable with predecessor models, we are confident that the HSA series will usher in a new era in take-out robots.

Features

Speed

Optimum lightweight design for faster speed

Using our Optimum Design approach, we reduced the total body weight by 13% *1 and verified the world’s fastest take-out time in actual molding, at 0.27 sec. At that speed, take-out cycles are 25% shorter than with predecessor models.

Slim

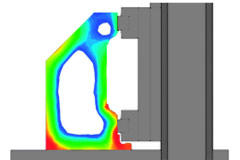

Optimum design of slimmer EOAT mounting part for reducing mold opening distance

We used our Optimum Design approach to make the EOAT flip part that enters the mold to grip and pull out products 38% *1 slimmer. This allows decreasing the mold open distance by 41 mm, which translates into shorter molding cycles.

Stable

Vibration control for ensuring positioning accuracy

Vibration control technology has been applied throughout the robot, including the use of CFRP (Carbon Fiber Reinforced Plastic) for the arm because of its good vibration-damping property and the application of our Optimum Design approach to the EOAT.

Smart

Easy-to-use, large 10.4-inch full color touch panel

Designed exclusively for the HSA series, the E-Touch II-K Controller is easily operated by simply touching icons on the screen. As a standard feature, it comes installed with Yushin’s Lead-through Teaching application that allows users to easily add points and timers. Users can also opt for the E-Touch Compact II Controller.

Sturdy

Built to withstand harsh environments

The controller is protected by guards on both sides. It is also dustproof and waterproof to an IP44 rating *2.

Savings

Air consumption reduced by 75% *1

HSA robots come with Yushin’s ECO Vacuum ® suction circuit that effectively lowers electricity bills and equipment investment, while, at the same time, protecting the global environment. *1 Compared to earlier Yushin products *2 E-Touch II-K Controller onlyOptimum design robots YC/YCII series

Optimally designed through joint research with Kyoto University

Optimum Design is what Yushin calls its use of CAE (Computer—Aided Engineering) to determine the theoretically best configuration of a robot based on its mechanisms and movements. This approach has been used in recent years to make aircraft and automobiles lighter and more reliable. Yushin applied this approach to reduce the weight and control the vibrations of the YC series. As a result, power consumption and settling time have been respectively reduced by 26% and 72%, which puts users in position to improve their productivity.

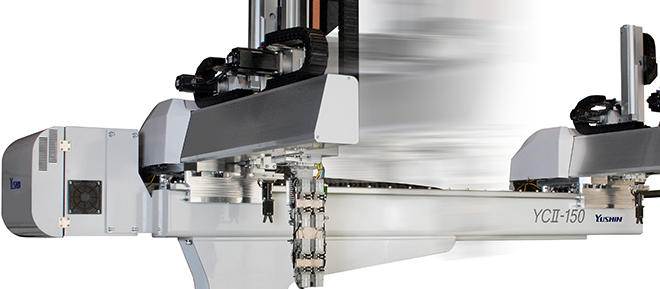

Optimum design robots YC/YCII series

Optimally designed through joint research with Kyoto University

Optimum Design is what Yushin calls its use of CAE (Computer—Aided Engineering) to determine the theoretically best configuration of a robot based on its mechanisms and movements. This approach has been used in recent years to make aircraft and automobiles lighter and more reliable. Yushin applied this approach to reduce the weight and control the vibrations of the YC series. As a result, power consumption and settling time have been respectively reduced by 26% and 72%, which puts users in position to improve their productivity.

Features

Energy-savings [1]

26% less power consumed than by predecessor robots

Because robot weight reduces by applying Optimum Design approach, lower duty motors are used.

Energy-savings [2]

75% less air consumed than by predecessor robots

Air consumption has been reduced by 75% from predecessor models by incorporating Yushin’s propriety ECO Vacuum circuit as a standard feature.

Vibration control

72% shorter settling time than predecessor robots

With the YC series, Optimum Design, CFRP and anti-vibration controls combine to shorten settling time (time required for vibrations to fall below a desired level) by 72%, which naturally shortens the full molding cycle.

Greater convenience

Predictive maintenance system and other new useful features for molding plants

The E-Touch Compact-YC is an easy-to-operate controller that can be carried in one hand. It incorporates a 7.5-inch full color touch panel of high visibility and a predictive maintenance system that displays warning messages if conditions that can develop into trouble are detected.

Winner of the JSME Technology Award

In 2011, Yushin was honored with the prestigious Technology Award of the Japan Society of Mechanical Engineers (JSME) for “developing high-performance take-out robots for molding machines by structural optimization”.

Winner of the JMF President’s Award for Energy Efficiency

In 2012, Yushin’s YC series of take-out robots for injection molding machine was recognized by the Japan Machinery Federation (JMF) with the JMF President’s Award at their Energy Efficient Machine Awards for the air consumption and weight reductions achieved through Optimum Design.

Economical all axis servo driving take-out robot

The SCII is a standard take-out robot of great cost-performance.

The driving axes are driven by digital servo motors. This enables smooth motion at both low and high speeds and flexible product release.

A stylish design minimizes the footprint.

Use of aluminum provides for lightweight construction, high speed take-out, and precise positioning.

Economical all axis servo driving take-out robot

The SCII is a standard take-out robot of great cost-performance.

The driving axes are driven by digital servo motors. This enables smooth motion at both low and high speeds and flexible product release.

A stylish design minimizes the footprint.

Use of aluminum provides for lightweight construction, high speed take-out, and precise positioning.

Features

Energy-savings

75% less air consumed than by predecessor robots

Air consumption has been reduced by 75% from predecessor models by incorporating Yushin’s propriety ECO Vacuum circuit as a standard feature.Vibration control

72% shorter settling time than predecessor robots

Design optimization employed for the SC Series accounts for factors such as natural oscillation and damping characteristics to reduce settling time. Used together with other vibration-damping technology, it greatly improves the SC’s vibration management.High Speed

Lighter Weight through Optimization Technology

Yushin R&D employed design optimization to enhance the shape and structure of many SC parts and components for lighter weight. The effort trimmed 16.0kg from the SC’s moving components, 10.1% lighter than the previous SA series model. The SC also enjoys 10.4% faster speeds than the SA without a motor size increase. But the SC was not simply lightweighted.Winner of the JSME Technology Award

E-touch Lite-SC

New TFT LCD touchscreen( 30,000 colors) for an even clearer display. Teaching data may be backed up on SD memory card and easily transferred to another robot.